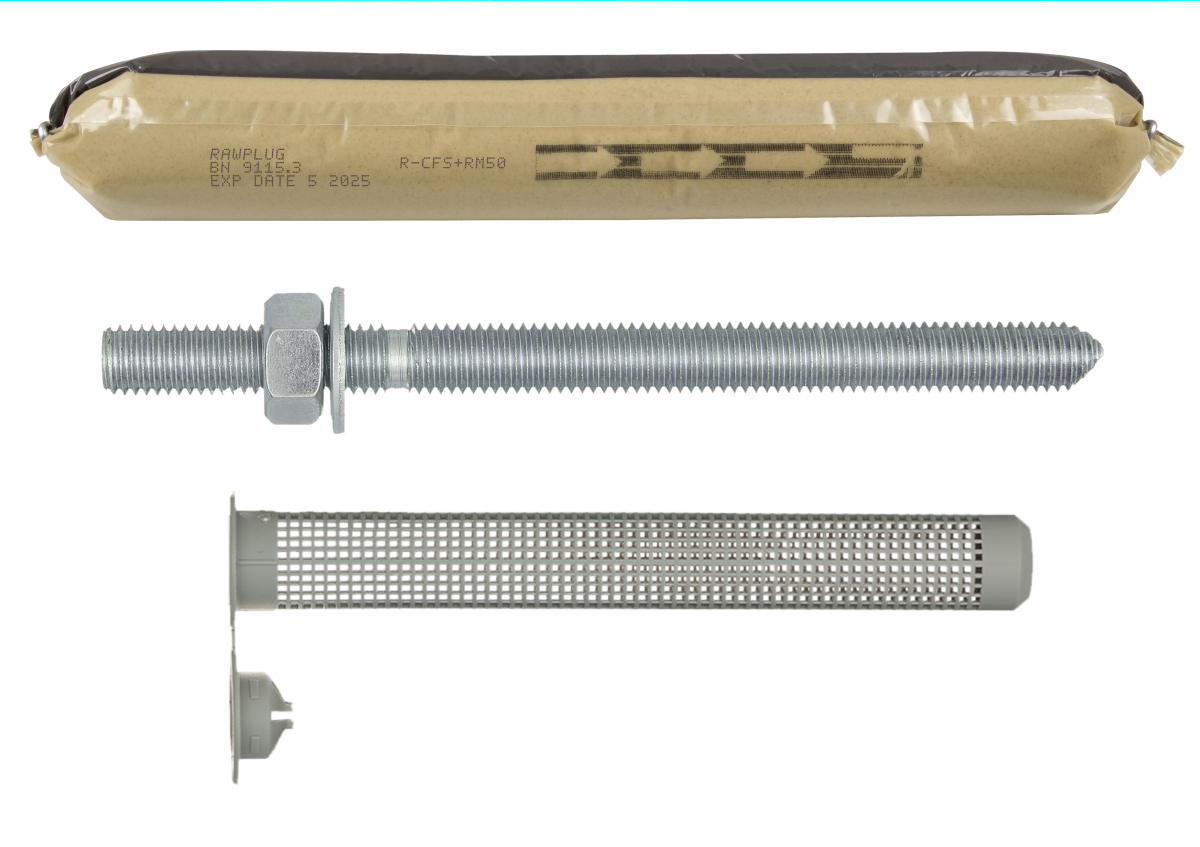

RM50 with Threaded Rods for Masonry (CFS+)

Universal polyester (styrene free) resin - European Approval for 15 substrates - Cartridge Free System (CFS+)

Features and benefits

- The most contemporary general use bonded anchor

- Approved for 15 substrates

- Quick, secure and simple installation

- Unique soft foil pack for less waste

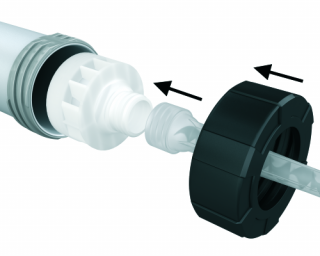

- Effortless extrusion due to the patented self-opening system with manual or battery dispenser guns

- Product with wide spectrum of use in the medium load capacity area

- Ideal for applications where mechanical anchors are not suitable

- Suitable for multiple use. Partly used product can be reused after fitting new nozzle

Product information

Product Code |

Resin |

Description / Resin Type |

Volume |

[ml] | |||

R-CFS+RM50-4 |

RM50 |

Styrene Free Polyester Resin |

300 |

R-CFS+RM50-600-8 |

RM50 |

Styrene Free Polyester Resin |

600 |

R-CFS+RM50-600-W |

RM50 |

Styrene Free Polyester Resin |

600 |

Base material

-

Solid Concrete Block

-

Lightweight Concrete Block

-

Solid Brick

-

Concrete Slab

-

Solid Sand-lime Brick

-

.png)

Aerated Concrete Block

-

Hollow Sand-lime Brick

-

Hollow Brick

-

Hollow Lightweight Concrete Block

Applications

- Balustrading

- Handrails

- Canopies

- Curtain walling

- Bathroom fittings

- Cable trays

- Barriers

- Cladding restraint

- Fencing & gates manufacturing and installation

- Pipework installation

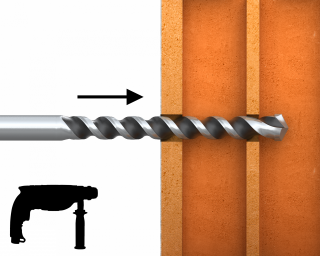

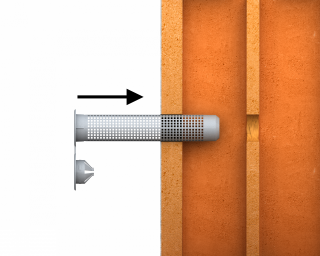

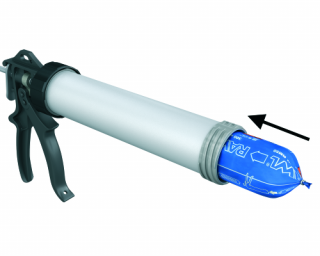

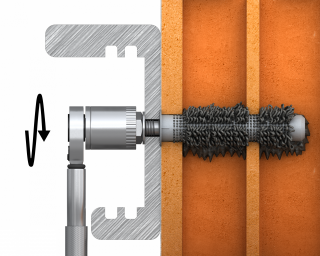

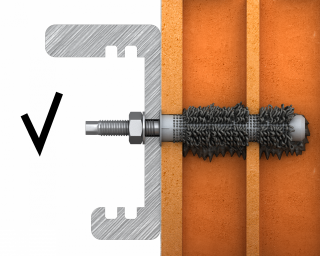

Installation guide

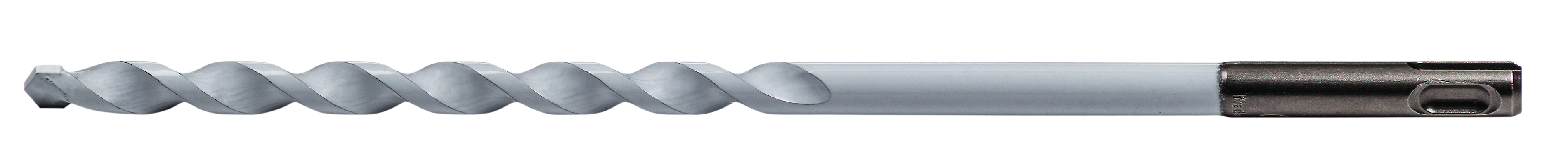

- Drill hole to the required diameter and depth for stud size being used.

- Insert foil into gun and attach nozzle.

- Solid substrates: Clean the drill hole thoroughly with brush and hand pump at least four times before installation.

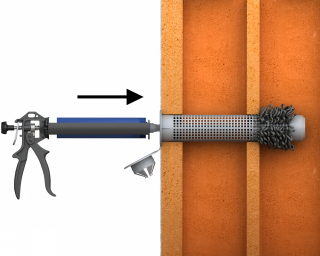

- Insert mesh sleeve into the hole with required depth and diameter

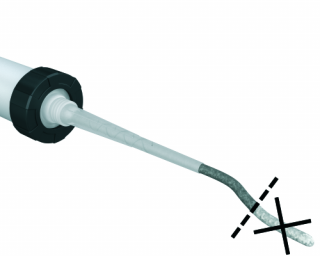

- Dispense to waste until even colour is obtained.

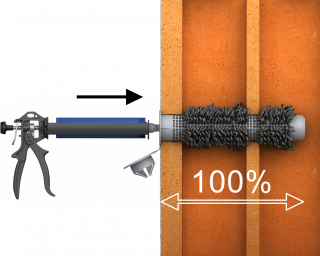

- Insert the mixer nozzle to the bottom of the drill hole and inject resin, slowly withdrawing the nozzle as the hole is filled to 100% of its depth.

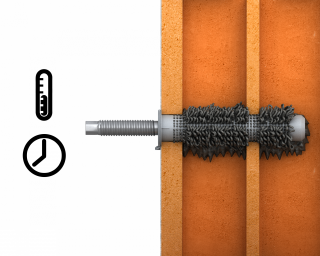

- Immediately insert the stud, slowly and with slight twisting motion. Remove any excess resin around the hole before it sets and leave it undisturbed until the curing time elapses.

- Attach fixture and tighten the nut to the required installation torque

Installation data

AERATED CONCRETE

Size |

M8 |

M10 |

M12 |

M16 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

10 |

12 |

14 |

18 |

Installation torque |

Tinst |

[Nm] |

3 |

4 |

6 |

10 |

Min. hole depth in substrate |

h0 |

[mm] |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

Min. installation depth |

hnom |

[mm] |

80 |

85 |

95 |

105 |

Min. spacing |

smin |

[mm] |

50 |

50 |

50 |

54 |

Min. edge distance |

cmin |

[mm] |

50 |

50 |

50 |

54 |

CERAMIC SOLID SUBSTRATES

Size |

M8 |

M10 |

M12 |

M16 |

||

Thread diameter |

d |

[mm] |

8 |

10 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

10 |

12 |

14 |

18 |

Installation torque |

Tinst |

[Nm] |

5 |

8 |

10 |

15 |

Min. hole depth in substrate |

h0 |

[mm] |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

Min. installation depth |

hnom |

[mm] |

80 |

85 |

95 |

105 |

Min. spacing |

smin |

[mm] |

50 |

50 |

50 |

54 |

Min. edge distance |

cmin |

[mm] |

50 |

50 |

50 |

54 |

HOLLOW SUBSTRATES

Size |

M8 |

M10 |

M12 |

M16 |

|||||

Thread diameter |

d |

[mm] |

8 |

8 |

10 |

10 |

12 |

12 |

16 |

Hole diameter in substrate |

d0 |

[mm] |

12 |

12 |

16 |

16 |

16 |

16 |

20 |

Installation torque |

Tinst |

[Nm] |

3 |

3 |

4 |

4 |

6 |

6 |

10 |

Min. hole depth in substrate |

h0 |

[mm] |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

hnom + 5 |

Min. installation depth |

hnom |

[mm] |

50 |

80 |

85 |

125 |

85 |

125 |

85 |

Min. spacing |

smin |

[mm] |

100 |

100 |

100 |

100 |

100 |

100 |

120 |

Min. edge distance |

cmin |

[mm] |

100 |

100 |

100 |

100 |

100 |

100 |

120 |

Plastic mesh sleeve size |

[mm] |

12x50 |

12x80 |

16x85 |

16x130 |

16x85 |

16x130 |

20x85 |

|

Minimum working and curing time

RM50

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

-20 |

- |

- |

5 |

-15 |

- |

- |

5 |

-10 |

- |

- |

5 |

-5 |

8 h |

70 |

5 |

0 |

4 h |

45 |

5 |

5 |

2 h |

25 |

10 |

10 |

1.5 h |

15 |

15 |

15 |

1 h |

9 |

20 |

20 |

45 |

5 |

25 |

30 |

30 |

2 |

25 |

35 |

- |

- |

25 |

40 |

- |

- |

RM50-S

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

-20 |

- |

- |

5 |

-15 |

- |

- |

5 |

-10 |

- |

- |

5 |

-5 |

24 h |

180 |

5 |

0 |

18 h |

120 |

5 |

5 |

12 h |

60 |

10 |

10 |

8 h |

45 |

15 |

15 |

6 h |

25 |

20 |

20 |

4 h |

15 |

25 |

30 |

1.5 h |

7 |

25 |

35 |

1 h |

6 |

25 |

40 |

45 |

5 |

*For wet concrete the curing time must be doubled

RM50-W

Resin temperature |

Concrete temperature |

Curing time* |

Working time |

[°C] |

[°C] |

[min] |

[min] |

5 |

-20 |

24 h |

45 |

5 |

-15 |

18 h |

30 |

5 |

-10 |

8 h |

20 |

5 |

-5 |

5 h |

11 |

5 |

0 |

2 h |

7 |

5 |

5 |

1 h |

5 |

10 |

10 |

45 |

2 |

15 |

15 |

30 |

1.5 |

20 |

20 |

15 |

1 |

25 |

30 |

- |

- |

25 |

35 |

- |

- |

25 |

40 |

- |

- |

*For wet concrete the curing time must be doubled

Contact us to get information about product availability and its price