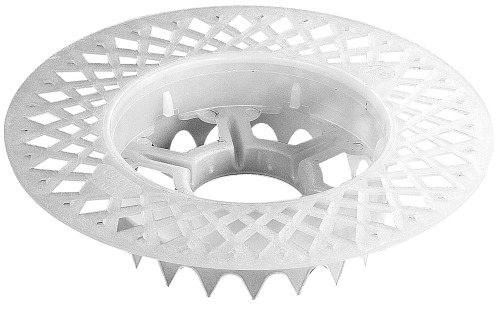

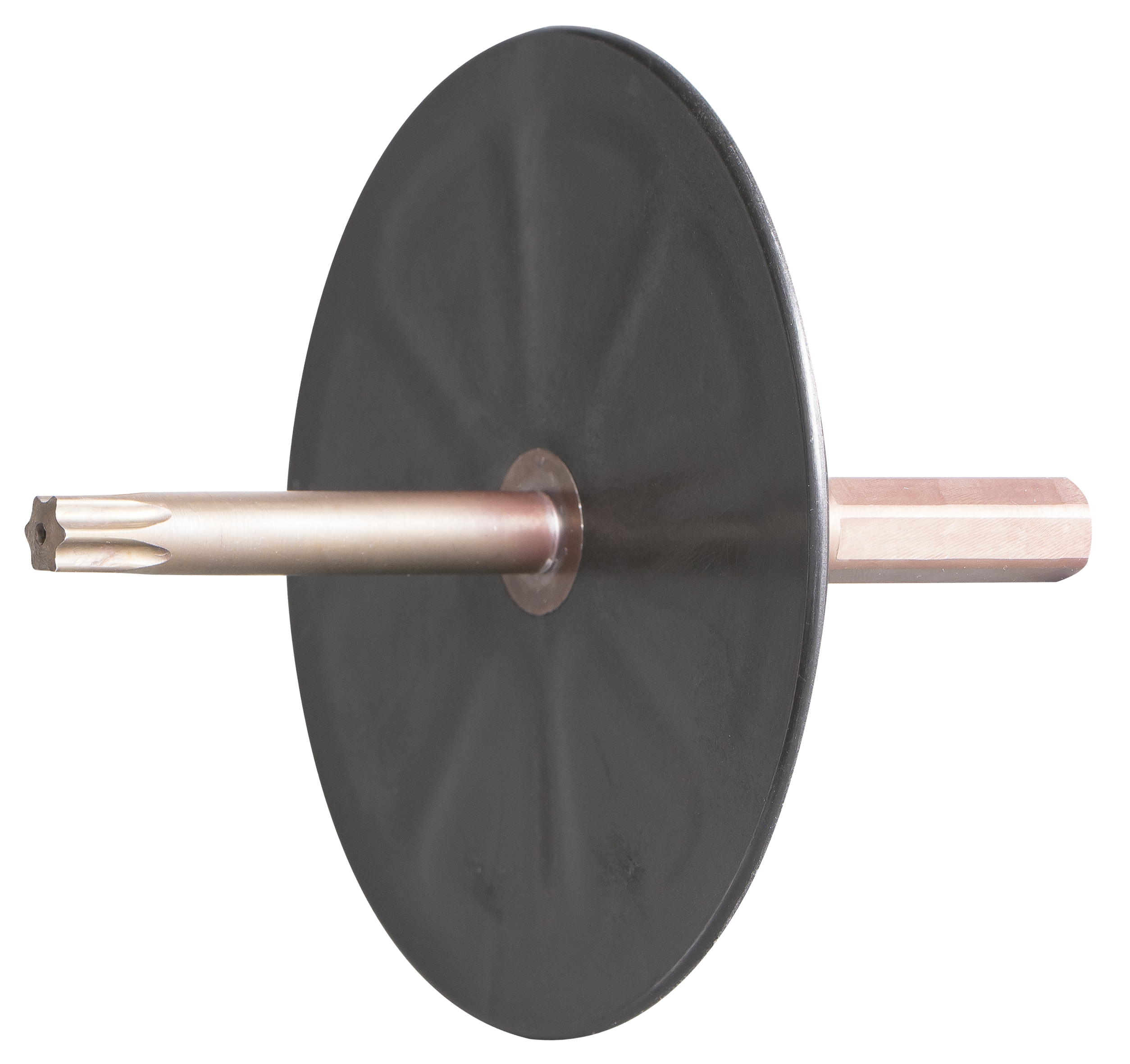

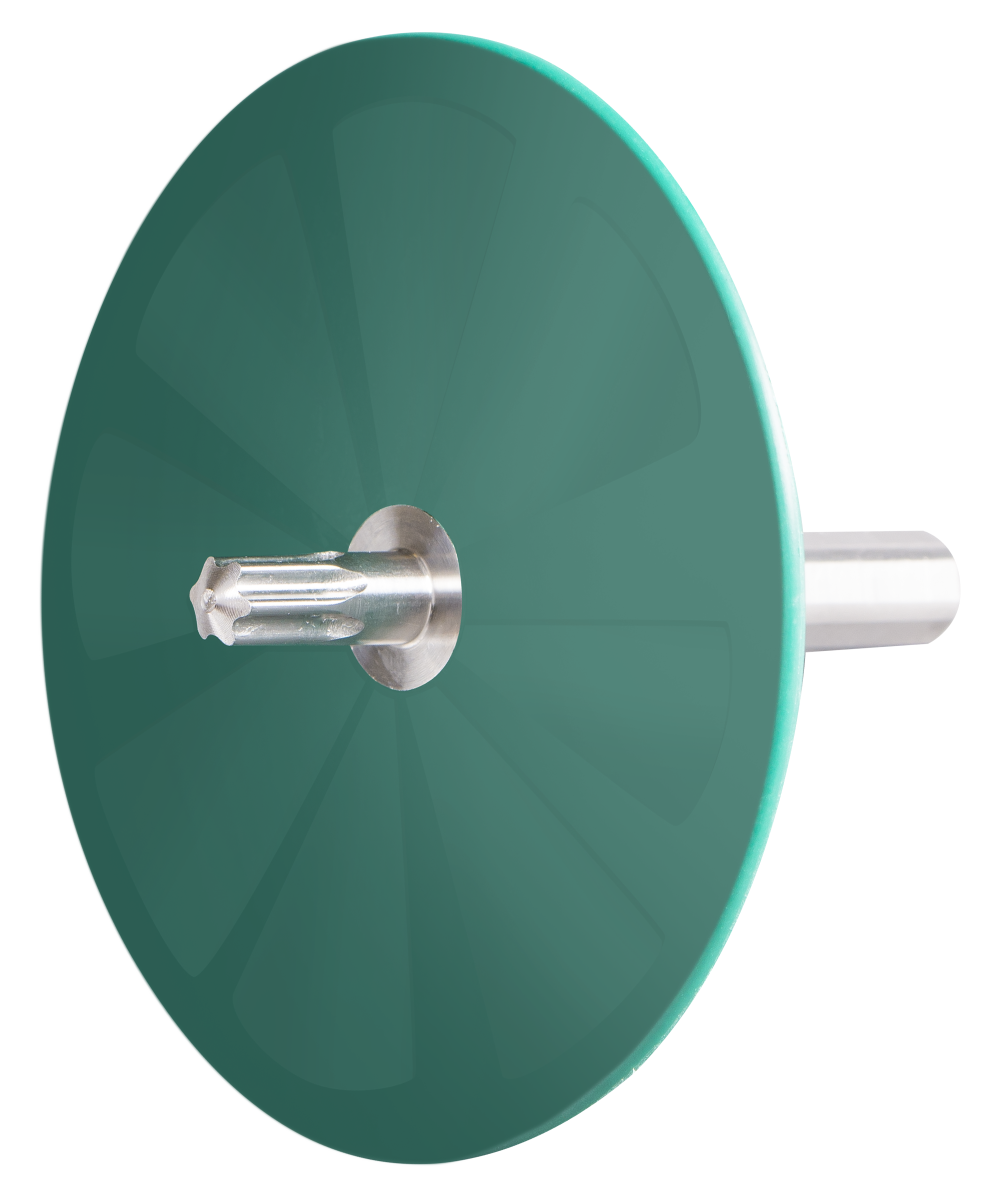

R-TFIX-CAP63-MW Mineral wool cap

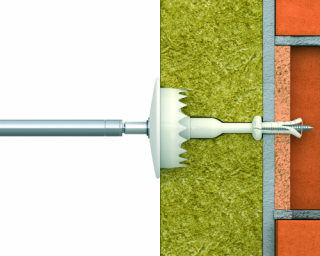

Post-installed mineral wool cap reduces heat transmission and results in a homogenous insulation surface

Features and benefits

- Cost-saving solution, as countersunk installation allows selection of shorter fixings.

- Results in homogeneous and smooth insulation surface

- Post-installed cap reduces heat transmission at fixing points

Product information

Product Code |

Material |

Diameter |

High |

d |

L |

||

[mm] | |||

R-TFIX-CAP90-MW |

mineral wool |

90 |

20 |

Base material

-

Mineral Wool Boards

Applications

- Mineral wool (MW) boards

Installation guide

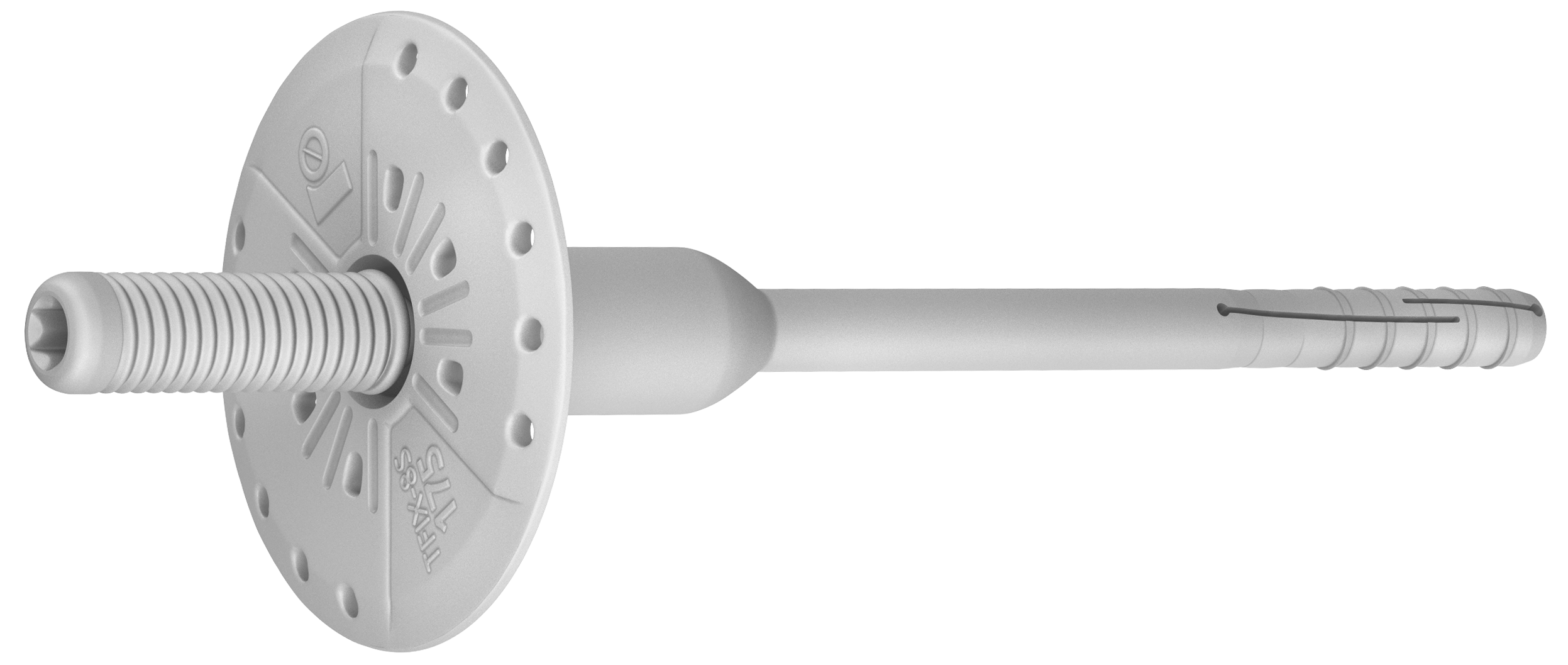

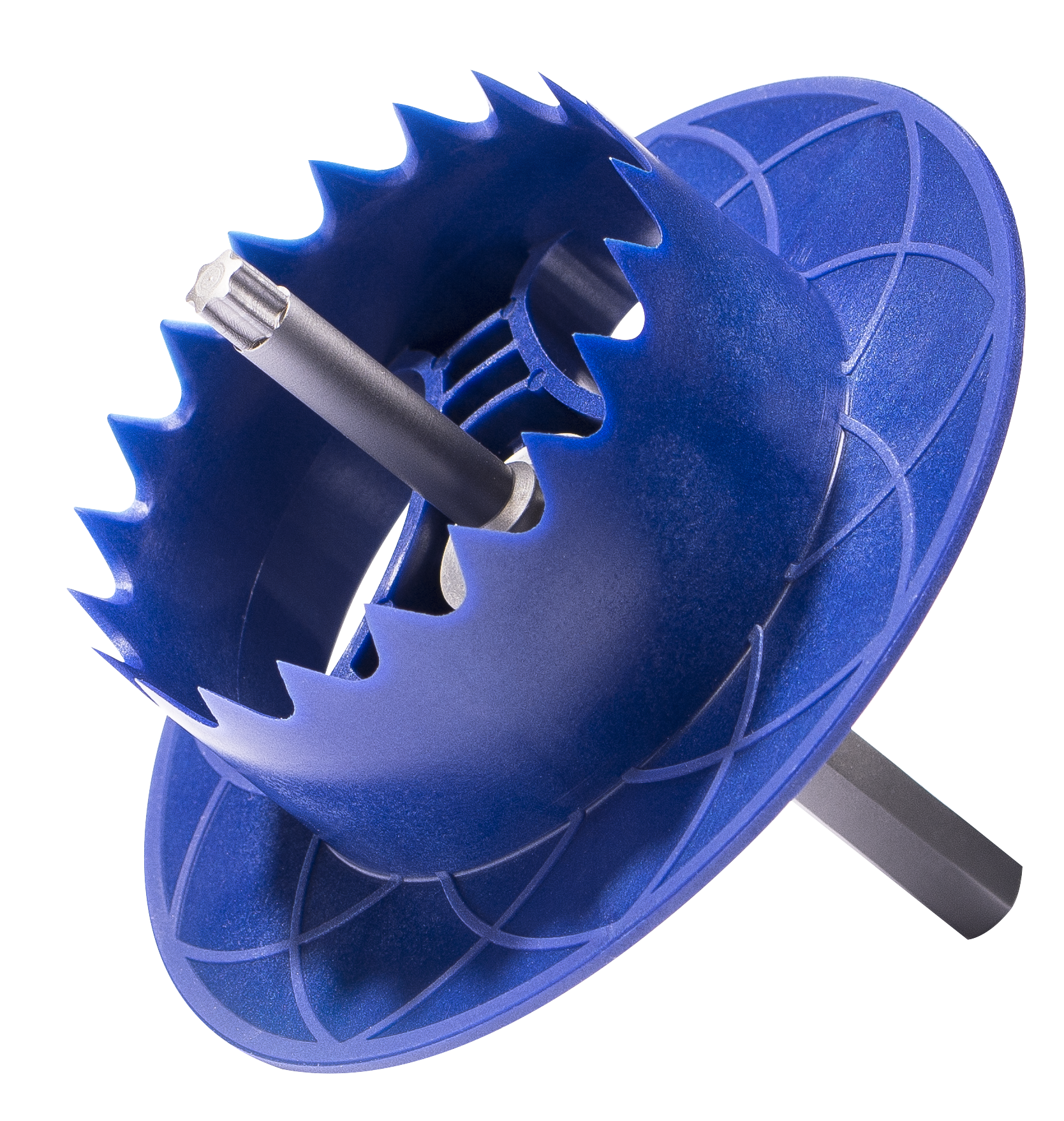

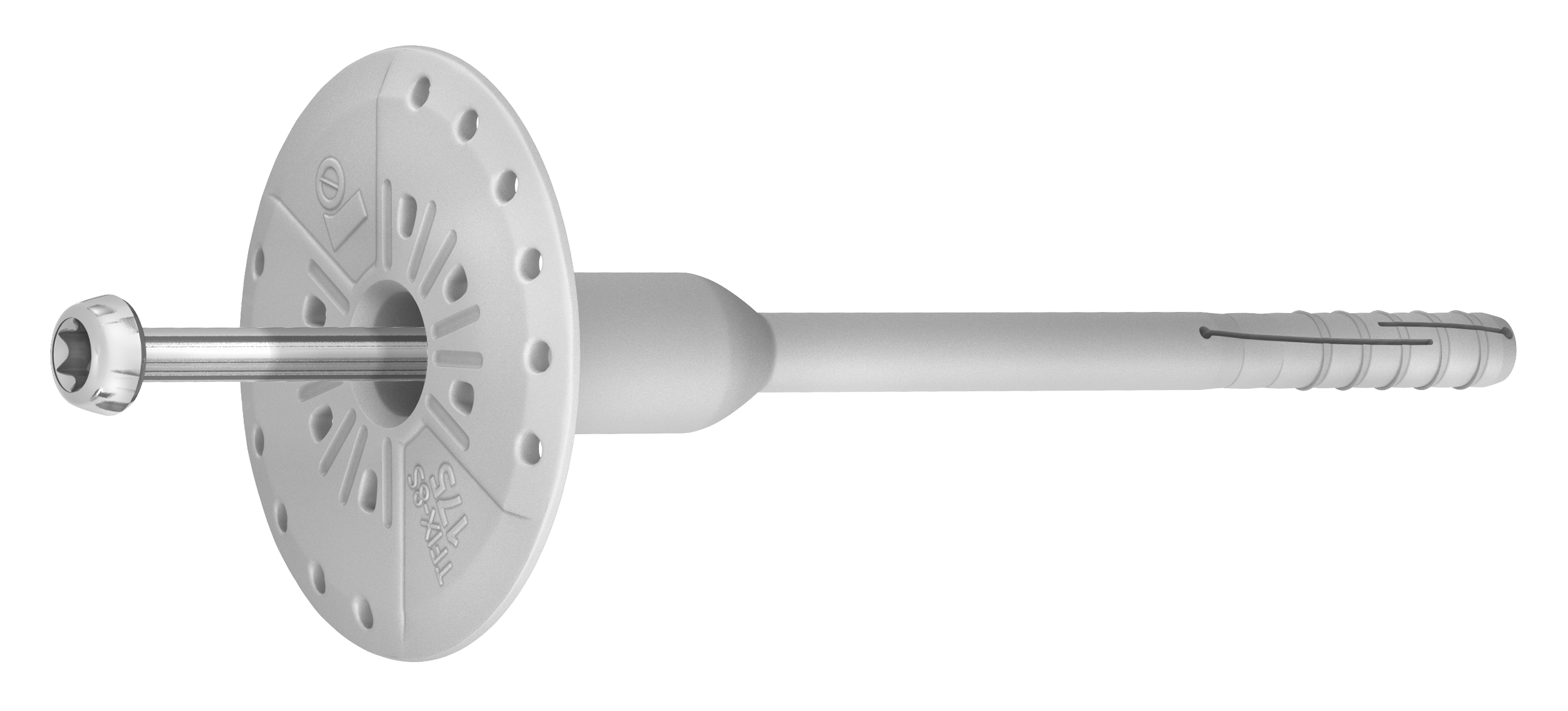

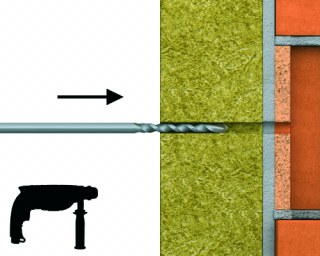

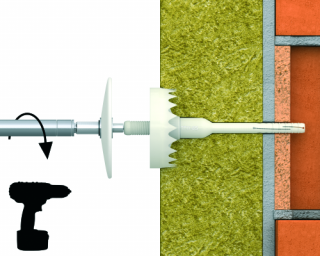

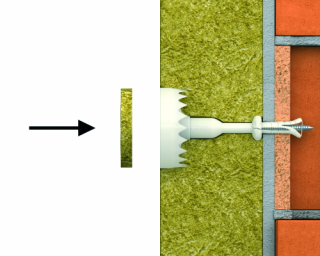

- Pre-assamble TFIX-8S-SETTING DEVICE with TFIX-8S fixing and than make installation of screw fixing

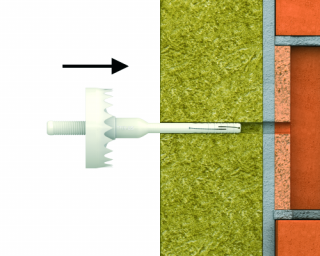

- Drill a hole of required diameter and depth

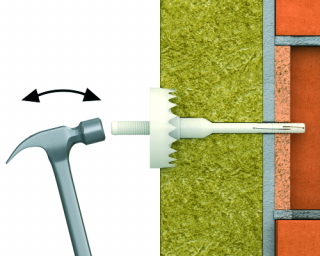

- Lightly tap the plastic sleeve through the insulation material into hole with a hammer, until fixing depth is reached

- When using the TFIX-DEVICE the teeth should be embedded in the insulation material after hammering.

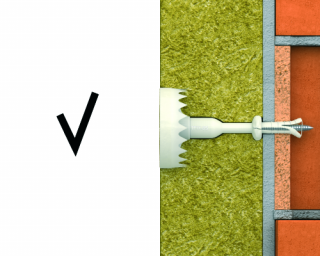

- Tighten screw (using special TFIX-8ST-TOOL setting tool) until fixing is secure and flush with insulation material

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in Aerated Concrete Block

- Drilling depth of min 40mm in A,B,C,D materials and 80mm in Aerated Concrete Block

- Insert cap into countersunk hole in insulation

Contact us to get information about product availability and its price