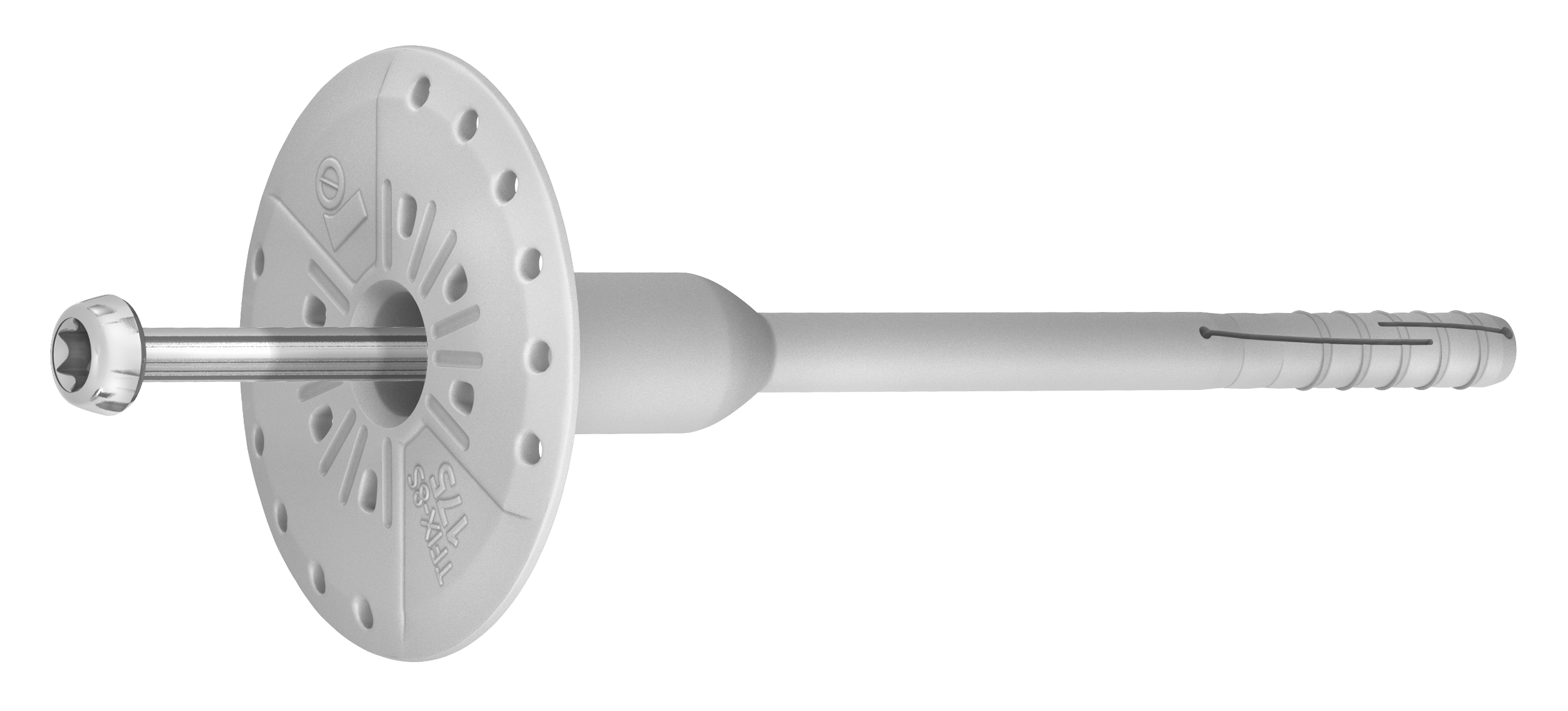

R-TFIX-CAP15-EPS Polystyrene cap

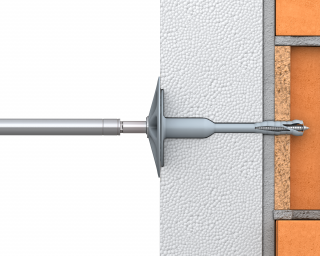

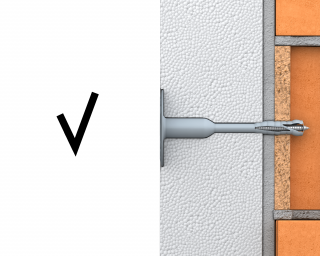

Post-installed polystyrene cap reduces heat transmission.

Features and benefits

- Post-installed cap reduces heat transmission at fixing points

Product information

Product Code |

Material |

Diameter |

High |

d |

L |

||

[mm] | |||

R-TFIX-CAP15-EPS-W |

white polystyrene |

15 |

25 |

R-TFIX-CAP15-EPS-G |

gray polystyrene |

15 |

25 |

Base material

-

boards_WebRes.png)

Polystyrene (EPS) Boards

-

Mineral Wool Boards

Applications

- Façade construction (ETICS)

- Polystyrene boards

- Mineral wool (MW) boards

- Polyurethane boards

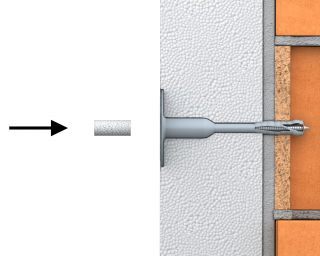

Installation guide

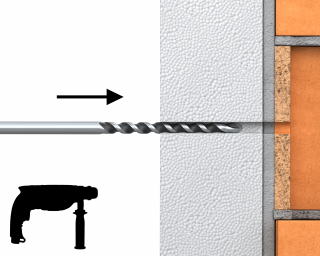

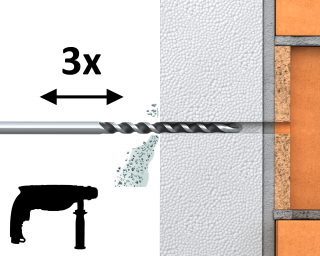

- Drill a hole of required diameter and depth.

- Drilling depth of min 35mm in A,B,C,D materials and 75mm in Aerated Concrete Block.

- Clean drilled hole 3 times.

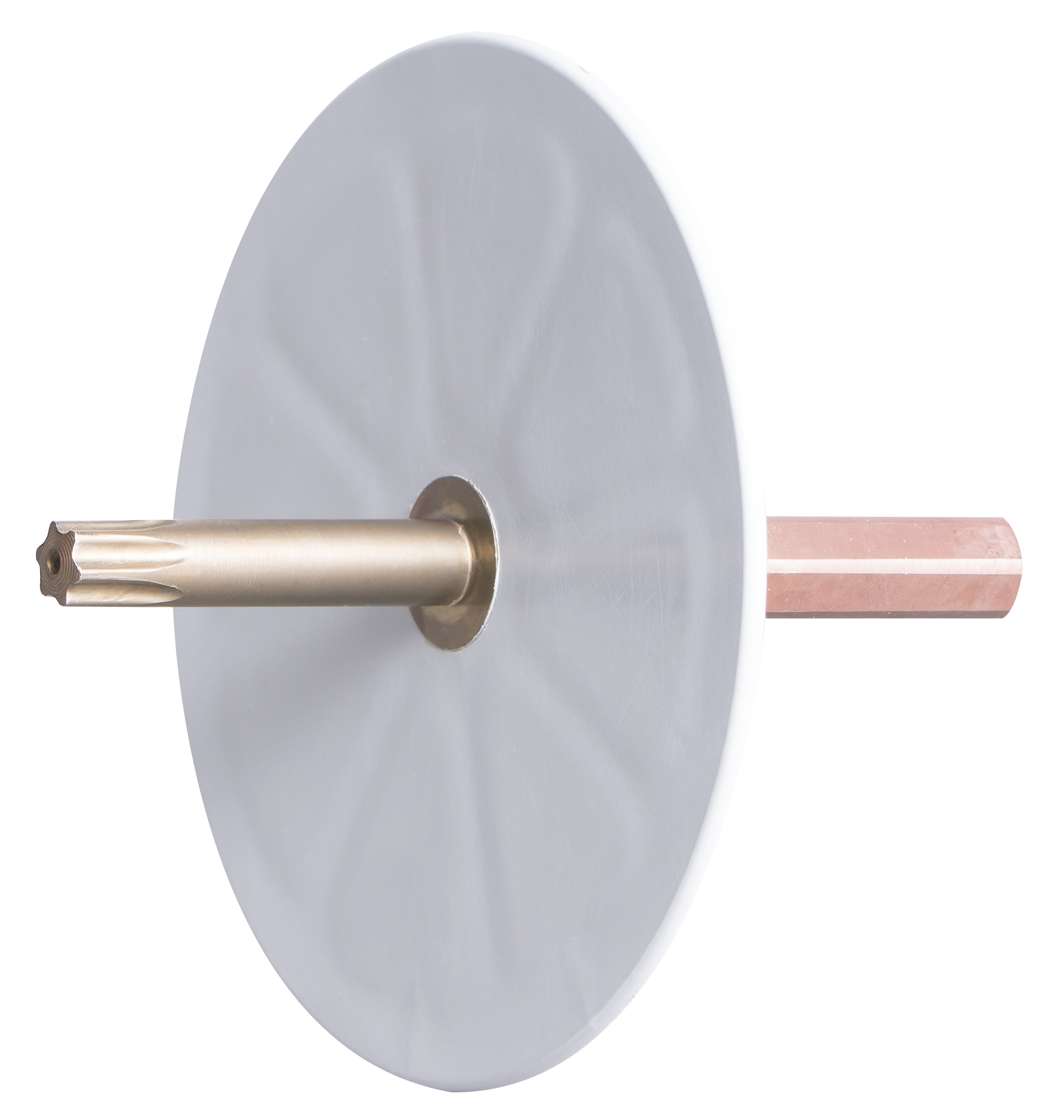

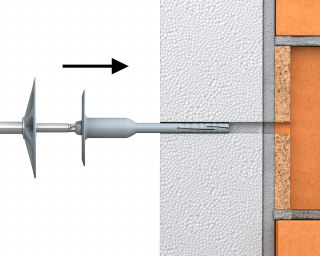

- Insert R-TFIX-TOOL-GREY into recess in head moulding of R-TFIX-8SX screw.

- Insert the fixing into the drilled hole.

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in Aerated Concrete Block.

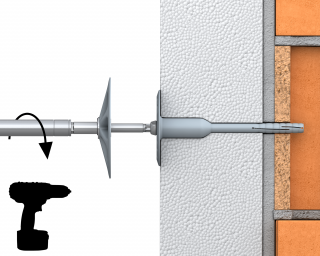

- Apply steady axial pressure, ensuring the disc of the setting tool is kept perpendicular to the fixing axis.

- Steadily drive in the screw with high revs until fixing is secure (when disc touches insulation surface).

Contact us to get information about product availability and its price