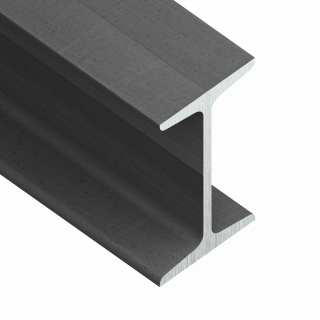

R-OCR-55/63 Zinc flake self-drilling screws up to 6mm

Special zinc flake corrosion-resistant coating for highly effective protection

Features and benefits

- Hardened screw's thread surface. High quality anti-corrosion coating guarantees resistance of 15 Kesternich cycles.

- Coloured polyester protective coating with a thickness of 45-50 um (RAL, NCS, RR), provides additional protection against corrosion. Various colours available to suit all metal sheet variants. UV stabilizers ensure colour quality over a long period of use.

- The shape of the thread and its height is designed for applications into sandwich panels and steel construction.

- Special zinc flake corrosion-resistant coating for anti-corrosion protection

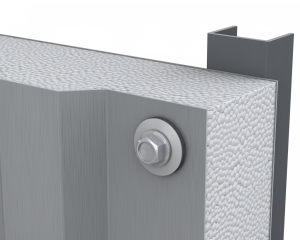

- Self vulcanizing EPDM washer. Temperature and UV resistant. The special shape of the washer ensures proper seating of the sealing material on the outer cladding material fixture which guarantees a proper seal.

- Drilling point - especially approach angle of self-drilling tip allows direct installation without predrilling up to 6mm

Product information

Size |

Product Code |

Screw |

Fixture |

Max. drilling thickness |

Washer size |

|||

Diameter |

Length |

Head size |

Max. thickness with washer |

|||||

d |

d1 |

l |

S |

tfix |

- |

- |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

||

Ø5.5/6.3 |

R-OCR-55/63090A19 |

5.5 |

6.3 |

90 |

8 |

65 |

6 |

19 |

R-OCR-55/63110A19 |

5.5 |

6.3 |

110 |

8 |

85 |

6 |

19 |

|

R-OCR-55/63125A19 |

5.5 |

6.3 |

125 |

8 |

100 |

6 |

19 |

|

R-OCR-55/63150A19 |

5.5 |

6.3 |

150 |

8 |

125 |

6 |

19 |

|

R-OCR-55/63175A19 |

5.5 |

6.3 |

175 |

8 |

150 |

6 |

19 |

|

R-OCR-55/63200A19 |

5.5 |

6.3 |

200 |

8 |

175 |

6 |

19 |

|

R-OCR-55/63230A19 |

5.5 |

6.3 |

230 |

8 |

205 |

6 |

19 |

|

R-OCR-55/63275A19 |

5.5 |

6.3 |

275 |

8 |

250 |

6 |

19 |

|

Base material

-

Structural Steel up to 6mm

Applications

- For fixing of: Composite panels to cold formed sections structures

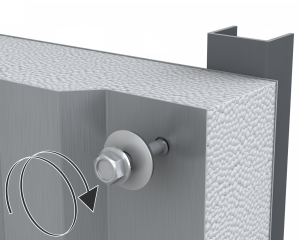

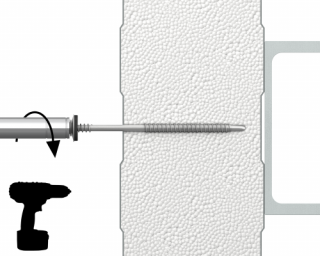

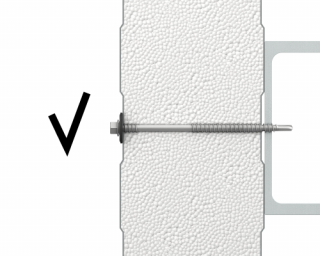

Installation guide

- Magnetic driver must be used.

- Lowest torque setting on impact screwdriver to start.

- Reduce speed when the washer starts to deform.

- Use a cordless Impact screwdriver. Note: Never use a power drill.

- For installation please use screwdriver of load capacity 1600 - 2000 rpm with regulated trogue.

Installation data

Size |

Ø5.5/6.3 |

||

Wrench size |

Sw |

[mm] |

8 |

Min. substrate thickness |

hmin |

[mm] |

1.5 |

Max. substrate thickness |

hmax |

[mm] |

6 |

Min. spacing |

smin |

[mm] |

30 |

Min. edge distance |

cmin |

[mm] |

10 |

Screw diameter |

d |

[mm] |

5.5/6.3 |

Contact us to get information about product availability and its price