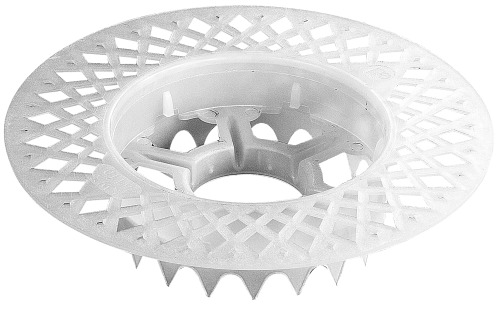

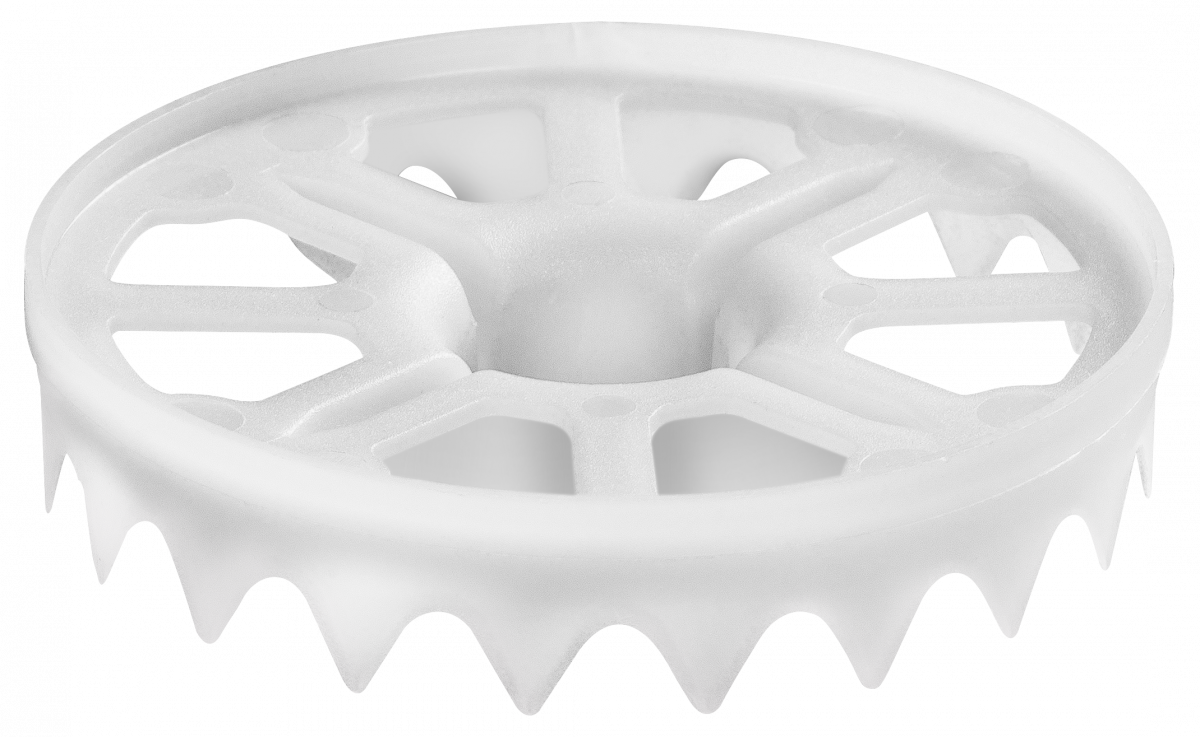

R-KWX Insulation retaining plate with perforator

Joining retaining plate with perforator for countersunk installation in mineral wool insulation boards

Features and benefits

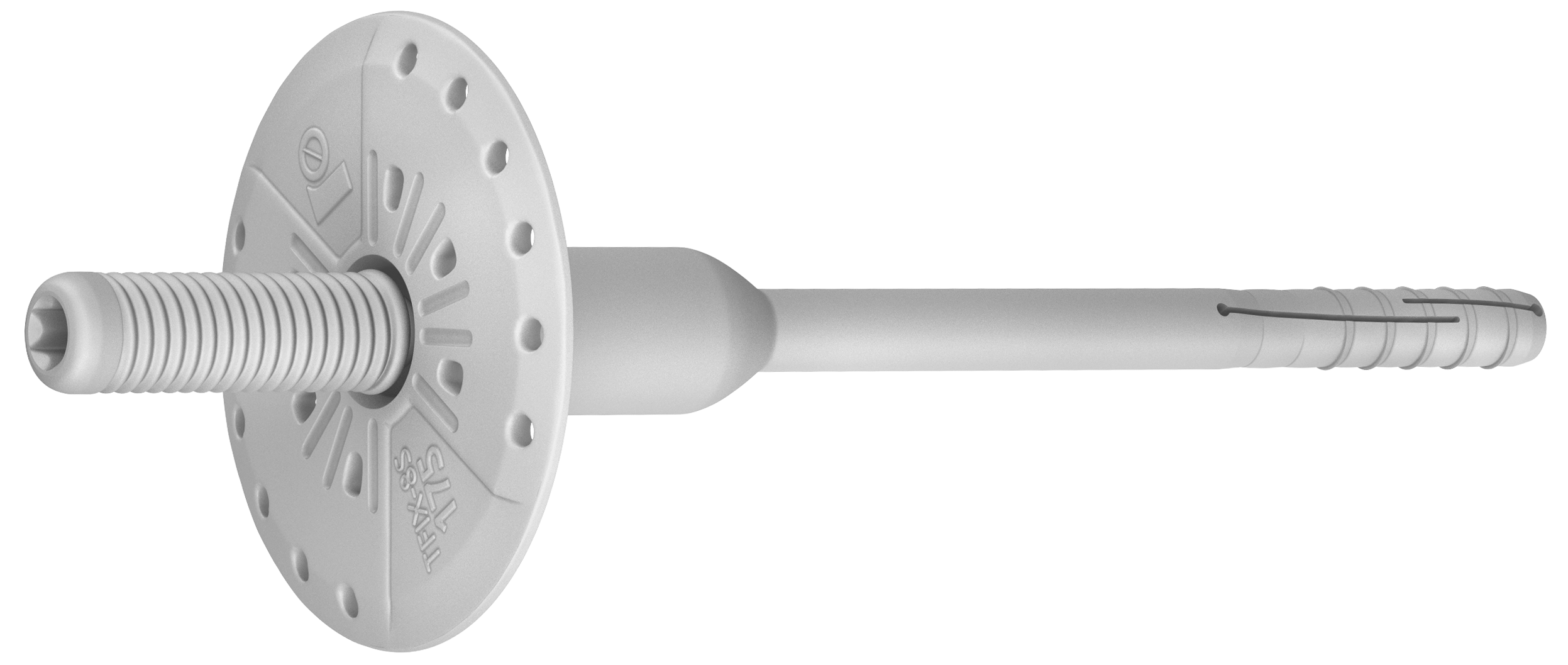

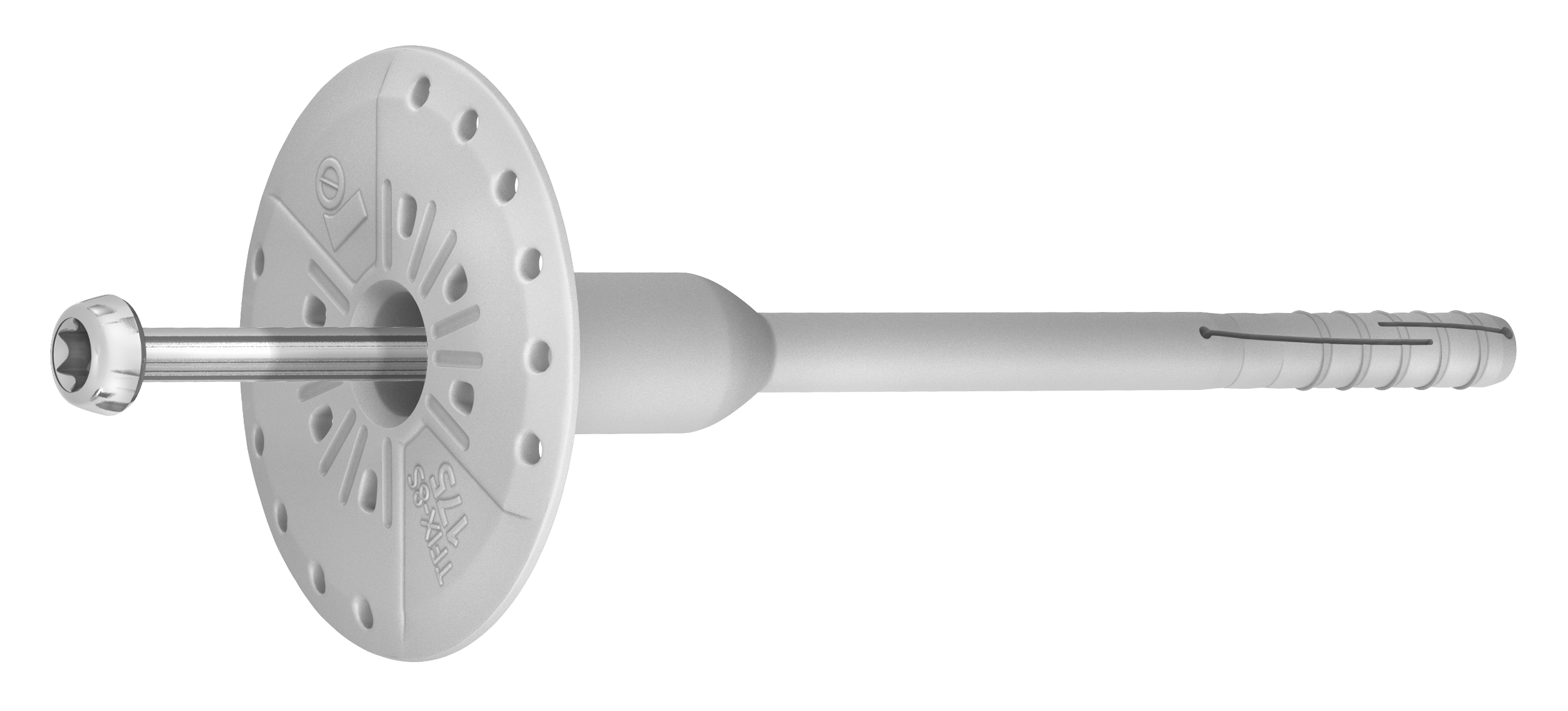

- Usage always with screw-in insulation fixing eg. R-TFIX-8SX / KWX

- Wide retaining plate improve pull-through insulation loads for the fixing point

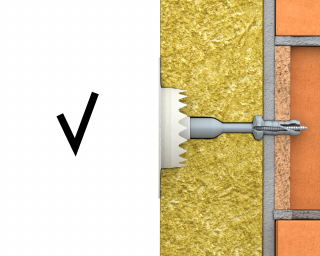

- Allows countersunk installation into all mineral wool-insulation boards with minimal lateral tensile strength and phenolic board

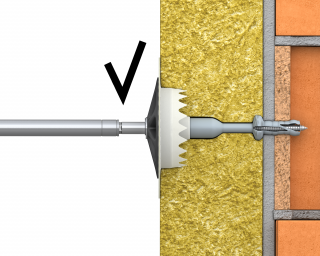

- Accurate countersunk setting automatically sets the fixing flush with the insulation layer

- Permanent contact pressure

- No additional installation tool required

- Quick and easy installation

- Compatible with TFIX-8S-MW insulation cap

Product information

Size |

Product Code |

Fixing |

Drill diameter |

Fixing |

Plate diameter |

Length |

|||

D |

Ø |

L |

||

[mm] | ||||

63,5 |

R-KWX-63 |

63.5 |

63.5 |

16.5 |

110 |

R-KWX-110 |

110 |

63.5 |

13.7 |

For use also with

-

boards_WebRes.png)

Polystyrene (EPS) Boards

-

Mineral Wool Boards

Applications

- External Thermal Insulation Composite Systems (ETICS)

Installation guide

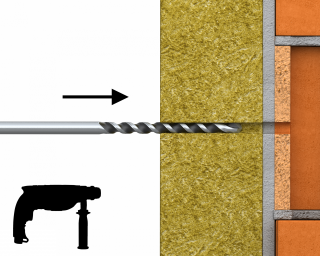

- Drill a hole of required diameter and depth

- Drilling depth of min 35mm in A,B,C,D materials and 75mm in Aerated Concrete Block.

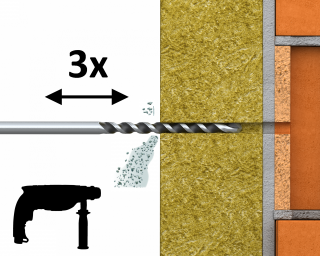

- Clean drilled hole 3 times.

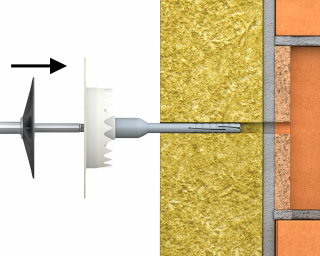

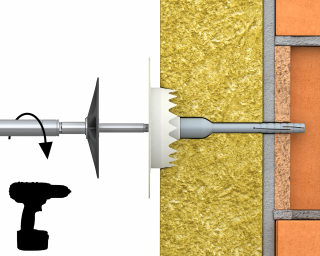

- Insert R-TFIX-TOOL-BLACK into recess in head moulding of R-TFIX-8SX screw.

- Insert the fixing into the drilled hole.

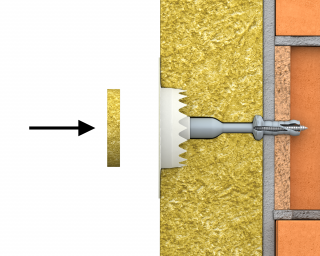

- When using the KWX-63 the teeth should be embedded in the insulation material after hammering.

- Embedment depth of min 25mm in A,B,C,D materials and 65mm in Aerated Concrete Block.

- Apply steady axial pressure, ensuring the disc of the setting tool is kept perpendicular to the fixing axis.

- Steadily drive in the screw with high revs until fixing is secure (when disc touches insulation surface).

Contact us to get information about product availability and its price