R-FF1-N-L-DT Nylon frame fixing countersunk in corrosion-resistant coating

Universal frame fixing with countersunk screw in corrosion-resistant coating for many applications

Features and benefits

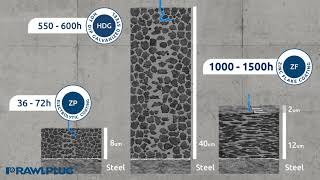

- Special zinc flake corrosion-resistant coating for anti-corrosion protection

- The countersunk plug for flush fixing of soft material (eg. timber)

- Specially-formulated nylon allows best performance installation for use in all base material categories according to ETAG 020 (A, B, C, D)

- Internal plug geometry designed to fit the screw head

- Plug design ensures multi-axis expansion

Product information

Size |

Product Code |

Plug |

Screw |

Fixture |

Screw drive |

||||

Diameter |

Length |

Diameter |

Length |

Max. thickness |

Hole diameter |

||||

d |

l |

d1 |

L1 |

tfix 50 |

tfix 70 |

df |

|||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

- |

||

Ø8 |

R-FF1-N-08L080/ZF |

7.8 |

80 |

5.8 |

87 |

30 |

10 |

8 |

T30 |

R-FF1-N-08L100/ZF |

7.8 |

100 |

5.8 |

107 |

50 |

30 |

8 |

T30 |

|

R-FF1-N-08L120/ZF |

7.8 |

120 |

5.8 |

127 |

70 |

50 |

8 |

T30 |

|

R-FF1-N-08L140/ZF |

7.8 |

140 |

5.8 |

147 |

90 |

70 |

8 |

T30 |

|

R-FF1-N-08L160/ZF |

7.8 |

160 |

5.8 |

167 |

110 |

90 |

8 |

T30 |

|

Ø10 |

R-FF1-N-10L080/DT |

9.8 |

80 |

7 |

87 |

30 |

10 |

10 |

T40 |

R-FF1-N-10L100/DT |

9.8 |

100 |

7 |

107 |

50 |

30 |

10 |

T40 |

|

R-FF1-N-10L120/DT |

9.8 |

120 |

7 |

127 |

70 |

50 |

10 |

T40 |

|

R-FF1-N-10L140/DT |

9.8 |

140 |

7 |

147 |

90 |

70 |

10 |

T40 |

|

R-FF1-N-10L160/DT |

9.8 |

160 |

7 |

167 |

110 |

90 |

10 |

T40 |

|

R-FF1-N-10L200/DT |

9.8 |

200 |

7 |

207 |

150 |

130 |

10 |

T40 |

|

R-FF1-N-10L240/DT |

9.8 |

240 |

7 |

247 |

190 |

170 |

10 |

T40 |

|

R-FF1-N-10L300/DT |

9.8 |

300 |

7 |

307 |

250 |

230 |

10 |

T40 |

|

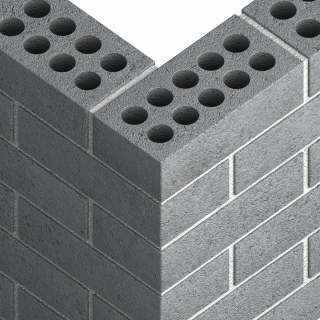

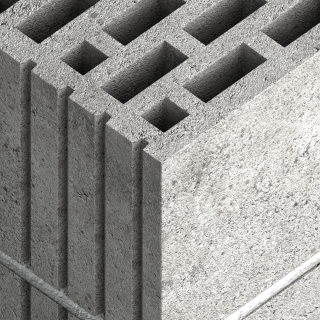

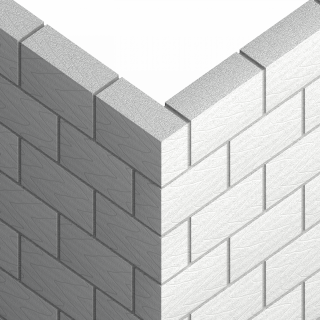

Base material

-

Concrete ≥ C12/15 (Use category A)

-

Solid Brick (Use category B)

-

Solid Sand-lime Brick (Use category B)

-

Hollow Brick (Use category C)

-

Hollow Sand-lime Brick (Use category C)

-

Hollow Lightweight Concrete Block (Use category D)

-

Aerated Concrete Block (Use category D)

-

Cracked concrete ≥ C12/15 (Use category A)

Applications

- Door and window frames

- Garage doors

- Gates

- Industrial doors

- Facade (substructures made of wood and metal)

- Wall cabinets

- Satelite dishes

- Shelves

- Handrails

- Cable trays

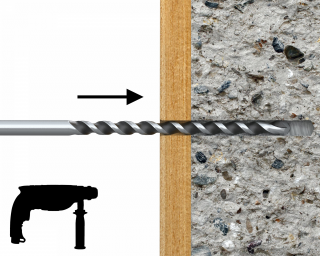

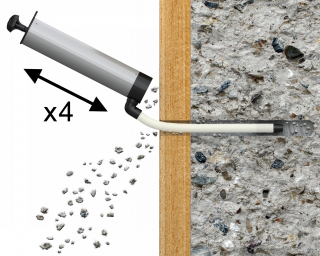

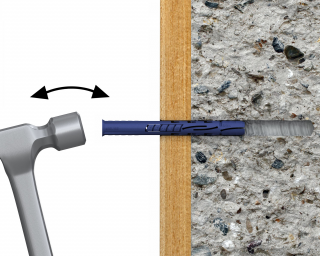

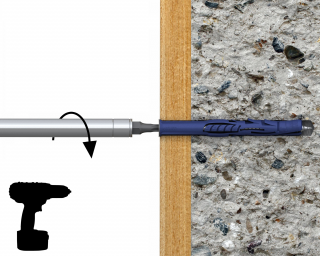

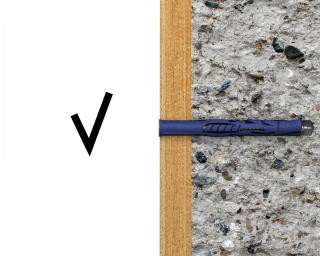

Installation guide

- Drill a hole of required diameter and depth

- With a hammer, lightly tap the plug through the fixture into hole until fixing depth is reached

- Tighten the FF1 screw

Installation data

Substrate |

A, B, C |

D |

A, B, C |

A, B, C |

D |

||

Hole diameter in substrate |

d0 |

[mm] |

8 |

8 |

10 |

10 |

10 |

Min. hole depth in substrate |

h0 |

[mm] |

60 |

80 |

60 |

80 |

80 |

Min. installation depth |

hnom |

[mm] |

50 |

70 |

50 |

70 |

70 |

Min. substrate thickness |

hmin |

[mm] |

100 |

100 |

100 |

100 |

100 |

Min. spacing |

smin |

[mm] |

60 |

200 |

90 |

95 |

70 |

Min. edge distance |

cmin |

[mm] |

60 |

100 |

80 |

80 |

70 |

Max. installation torque |

Tinst |

[Nm] |

9 |

3.6 |

16 |

16 |

4.3 |

Screw drive |

- |

[-] |

T30 |

T30 |

T40 |

T40 |

T40 |

Diameter |

d |

[mm] |

8 |

8 |

10 |

10 |

10 |

Effective embedment depth |

hef |

[mm] |

50 |

70 |

50 |

70 |

70 |

Contact us to get information about product availability and its price