OCWS Stainless steel self-drilling screws

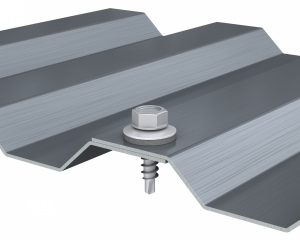

Stainless steel self drilling screw with reduced drilling point guarantees optimum tightness of the fastening

Features and benefits

- Stainless steel self drilling screw made with BIMETAL

- Hardened surface of the thread (flexible core). Corrosion resistant zinc coating has a thickness of no less than 12um.

- The full length thread design prevents twisting and allows application without a washer. Furthermore the specific shape and type of thread allow metal sheets to be connected together.

- Self vulcanizing EPDM washer. Temperature and UV resistant. The special shape of the washer ensures proper seating of the sealing material on the outer cladding material fixture which guarantees a proper seal.

- The drill point is designed to provide a fast and hassle-free installation in wood. Sharp point of the drill prevents movement of the surface of the fixture.

- Reduced drilling point ensures optimal tightness and correct hole diameter in thin metal sheets.

Product information

Size |

Product Code |

Screw |

Fixture |

Max. drilling thickness |

Washer size |

RAL Colour |

|||

Diameter |

Length |

Head size |

Max. thickness with washer |

Max. thickness without washer |

|||||

d |

l |

S |

tfix |

tfix |

- |

- |

- |

||

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

[mm] |

- |

||

Ø4.8 |

OCWS-48019 |

4.8 |

19 |

8 |

7 |

10 |

2.5 |

14 |

- |

OCWS-48019S16 |

4.8 |

19 |

8 |

7 |

10 |

2.5 |

14 |

- |

|

Ø5.5 |

OCWS-55025 |

5.5 |

25 |

8 |

8 |

11 |

3 |

14, 16, 19 |

- |

OCWS-55025S16 |

5.5 |

25 |

8 |

8 |

11 |

3 |

14, 16, 19 |

- |

|

Ø4.8 |

OCWS-48019TS14 |

4.8 |

19 |

8 |

7 |

10 |

2.5 |

14 |

- |

Ø5.5 |

OCWS-55025S14 |

5.5 |

25 |

8 |

8 |

11 |

3 |

14, 16, 19 |

- |

OCWS-55025S19 |

5.5 |

25 |

8 |

8 |

11 |

3 |

14, 16, 19 |

- |

|

Ø4.8 |

OCWS-48019S147035 |

4.8 |

19 |

8 |

7 |

10 |

2.5 |

14 |

7035 |

OCWS-48019S149006 |

4.8 |

19 |

8 |

7 |

10 |

2.5 |

14 |

9006 |

|

OCWS-48019S149010 |

4.8 |

19 |

8 |

7 |

10 |

2.5 |

14 |

9010 |

|

Ø5.5 |

OCWS-55025S169006 |

5.5 |

25 |

8 |

8 |

11 |

3 |

14, 16, 19 |

9006 |

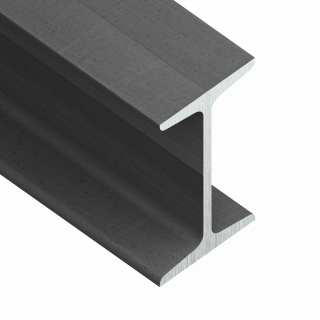

Base material

-

Structural Steel

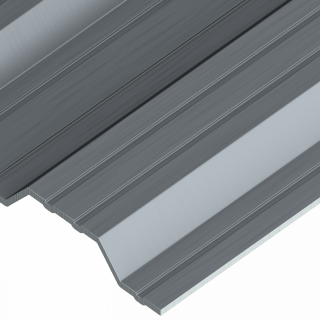

-

Metal Sheet & Profiles

Applications

- For fixing of: Overlapping sheet connection

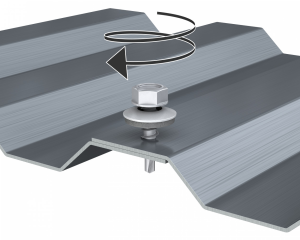

Installation guide

- Screw must be installed at 90 degrees to substrate.

- Special driver must be used.

- Lowest torque setting on impact screwdriver to start.

- Reduce speed when the washer starts to deform.

- Use a cordless Impact screwdriver. Note: Never use a power drill.

- For installation please use screwdriver of load capacity 1600 - 2000 rpm with regulated trogue.

Installation data

Size |

Ø4.8 |

Ø5.5 |

||

Hole diameter in substrate |

d0 |

[mm] |

- |

- |

Min. hole depth in substrate |

h0 |

[mm] |

- |

- |

Min. installation depth |

hnom |

[mm] |

- |

- |

Min. substrate thickness |

hmin |

[mm] |

0.4 |

1 |

Min. spacing |

smin |

[mm] |

30 |

30 |

Min. edge distance |

cmin |

[mm] |

10 |

10 |

Wrench size |

Sw |

[mm] |

8 |

8 |

Screw diameter |

d |

[mm] |

4.8 |

5.5 |

Contact us to get information about product availability and its price